Uncoated Carbide End Mill Diameter D : 1/16 Length of Cut L1 : 0.250" Shank Diameter S : 1/16 Overall…

1/16 Carbide End Mill 3FL Alu. Uncoated Carbide End Mill Diameter D : 1/16 Length of Cut L1 : 0.250″ Shank Diameter S : 1/16 Overall Length L : 2″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces Ideal to cut : Aluminum, Copper, Brass, Plastic $ 12.50

7 in stock

Carbide End Mill Variable Helix Diameter D : 1/16 Length of Cut L1 : 0.250" Shank Diameter S : 1/16…

1/16 Vari-Helix 4FL Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/16 Length of Cut L1 : 0.250″ Shank Diameter S : 1/16 Overall Length L : 2″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 11.50

9 in stock

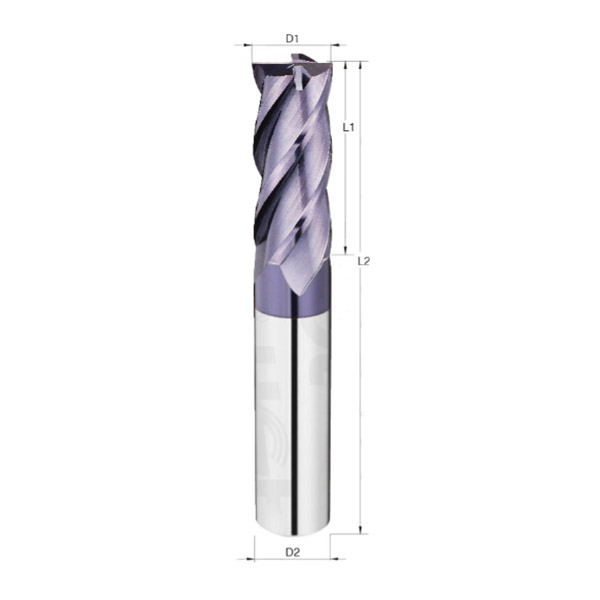

Suitable for Steel and Cast Iron Suitable for material up to 55HRC TiALN coating Helix-Angle : 35° Flute # :…

1/2 4-Flute Carbide End Mill Suitable for Steel and Cast Iron Suitable for material up to 55HRC TiALN coating Helix-Angle : 35° Flute # : 4 O.A.L : 3″ Flute Length : 1″ Brand : HGT $ 55.53

Out of stock

Uncoated Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.25" Shank Diameter S :…

1/2 Carbide End Mill 3FL Alu. Uncoated Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.25″ Shank Diameter S : 1/2 Overall Length L : 3″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 48.10

65 in stock

Uncoated Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.25" Shank Diameter S :…

1/2 Carbide End Mill 3FL Alu. CR0.020 Uncoated Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.25″ Shank Diameter S : 1/2 Overall Length L : 3″ Corner Radius R : 0.020″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 51.32

50 in stock

Uncoated Carbide End Mill with Long Reach Diameter D : 1/2 Length of Cut L1 : 2" Shank Diameter S…

1/2 Carbide End Mill 3FL Alu. Long Length Uncoated Carbide End Mill with Long Reach Diameter D : 1/2 Length of Cut L1 : 2″ Shank Diameter S : 1/2 Overall Length L : 4″ Efficient Cheap Evacuation Improved Surface Finished Ideal for Machining : Aluminum, Copper, Brass, Bronze, Plastic $ 72.77

5 in stock

Rougher Carbide End Mill Helix angle : 35º FSIN PVD Coated Ideal for machining Steel and general purpose Diameter D…

1/2 Carbide Roughing End Mill 4F Rougher Carbide End Mill Helix angle : 35º FSIN PVD Coated Ideal for machining Steel and general purpose Diameter D : 1/2 Length of Cut L1 : 1.25″ Shank Diameter S : 1/2 Overall Length L : 3″ Efficient Cheap Evacuation Reduced Cutting Forces Brand : 7Sieb $ 59.68

27 in stock

Rougher Carbide End Mill Helix angle : 45º Uncoated Ideal for machining ALU, Copper, Brass, Bronze, Plastic Diameter D :…

1/2 Carbide Roughing End Mill ALU 3F Rougher Carbide End Mill Helix angle : 45º Uncoated Ideal for machining ALU, Copper, Brass, Bronze, Plastic Diameter D : 1/2 Length of Cut L1 : 1.25″ Shank Diameter S : 1/2 Overall Length L : 3″ Brand : 7Sieb $ 69.40

30 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.250" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL 0.020″ Corner Radius Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.250″ Shank Diameter S : 1/2 Overall Length L : 3″ Corner Radius R : 0.020″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 49.70

93 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.250" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL 0.030″ Corner Radius Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.250″ Shank Diameter S : 1/2 Overall Length L : 3″ Corner Radius R : 0.030″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 51.36

18 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.250" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL 0.040″ Corner Radius Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.250″ Shank Diameter S : 1/2 Overall Length L : 3″ Corner Radius : 0.040″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 51.36

30 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.25" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut L1 : 1.25″ Shank Diameter S : 1/2 Overall Length L : 3″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 44.90

137 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 2" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL CR 0.020 Long Length Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 2″ Shank Diameter S : 1/2 Overall Length L : 4″ Corner Radius R : 0.020″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 77.80

50 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 1.25"" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL CR 0.030 Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 1.25″” Shank Diameter S : 1/2 Overall Length L : 3″ Corner Radius R : 0.030″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 51.36

30 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 2" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL CR 0.030 Long Length Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 2″ Shank Diameter S : 1/2 Overall Length L : 4″ Corner Radius R : 0.030″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 77.80

43 in stock

Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 2" Shank Diameter S : 1/2…

1/2 Vari-Helix 4FL Long Length Carbide End Mill Carbide End Mill Variable Helix Diameter D : 1/2 Length of Cut Lc : 2″ Shank Diameter S : 1/2 Overall Length L : 4″ Efficient Cheap Evacuation Improved Surface Finish Reduced Cutting Forces $ 69.44

47 in stock

Buy selection of Carbide End Mills for Long-Lasting Durability They are applicable in variety of milling operations from face and shoulder milling to profiling and grooving type.

The first physical aspect of an end mill is cutting diameter which in some cases might be different than the shank diameter which is to be gripped in the tool holder. End mills come in standard length or long version. Less number of flutes provide more room between the flutes and more chip load capacity for roughing or cutting soft materials.

Carbide End Mills with more flutes are better choices for general and finishing purposes producing less chatter.The end mill tip surface defines if it is a center cutting or non-center cutting. End Mills with corner rad can be a good choice for machining non-sharp corners and rough machining applications since the sharp End Mills are more susceptible to chipping. Ball nose End mills are so beneficial whenever the cutting edges are not perpendicular to end mill axis.

Solid Carbide End Mill Coatings Are a very important feature that should be considered when ordering an End Mill. They are made from Carbide which are very tough but brittle. The coatings cover the cutting edges and make them much harder and increase its temperature resistance significantly.