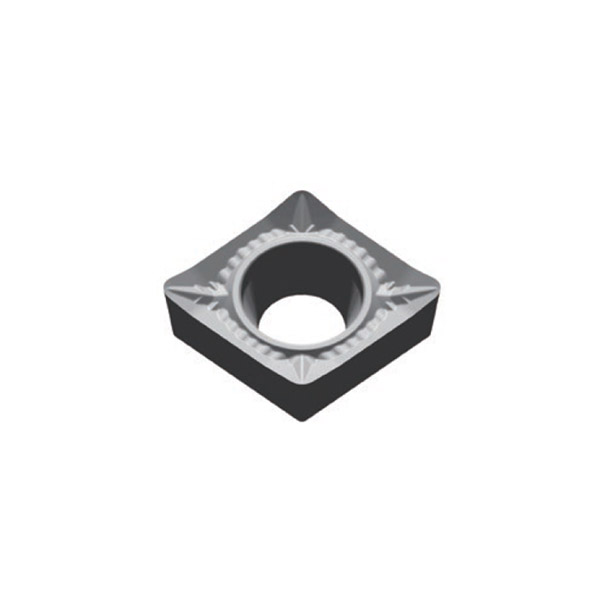

General Turning

Sort by

View

Carbide inserts consist of Tungsten Carbide (WC) and cobalt (Co). The tungsten carbide plays the hard part and the Cobalt holds the tungsten particles together.

The size of the grains of the tungsten carbide can change the properties of cemented carbide. Large grains create a softer material which wears more easily but is tougher. Small grains create harder material with more wear resistance but is more brittle. An Insert with small grains would be the best option to cut very hard materials. On the other hand, an Insert with larger grains would be the best choice for interrupted cuts. Cobalt is a much softer and tougher material than tungsten carbide therefore decreasing its portion will make the insert harder.

Cutting tool manufacturers use higher ratio of Cobalt on the outer layer of an insert than on the inside. The outer of the insert receives extra percentage of Cobalt which allows the insert body to get stronger cemented carbide composition. Once the proportions of the cobalt and tungsten carbide are determined, the process of making an insert begins. Powders of tungsten, carbon and cobalt are placed in a mill. The process mills the grains to the necessary size depending on the geometry of an insert. A mix of Alcohol and water is added to the process during the milling and a dark slurry is produced. The slurry is placed on a cyclone dryer where the liquids evaporate and the powder is stored.

In the next stage the powder is mixed with polyethylene glycol and then a press dies forms the materials into the shape of an insert. The pieces go into a furnace where are exposed to high heat for sintering. This process melts the polyethylene glycol which leads the shrinkage of the Insert to the final size.

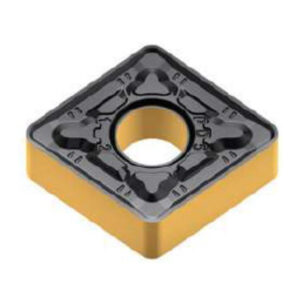

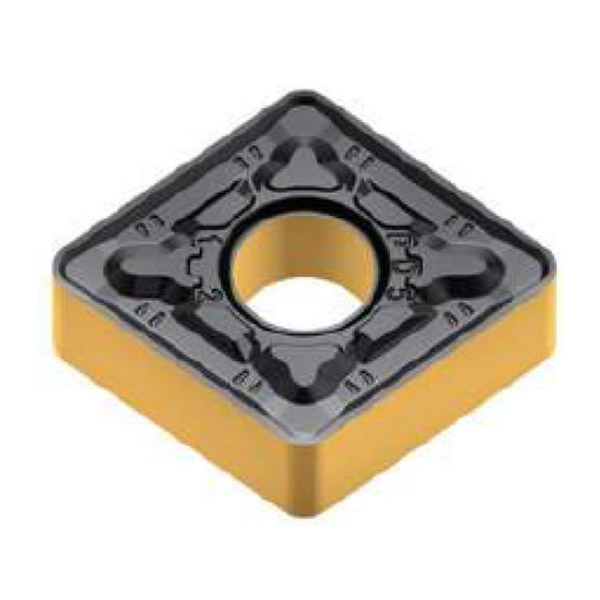

To achieve a high performance, inserts are coated. There are two common processes for applying a coating on Inserts. Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD). In CVD coating process, a metal is ionized by high electrical current followed by applying it to the insert via vapor condensation.

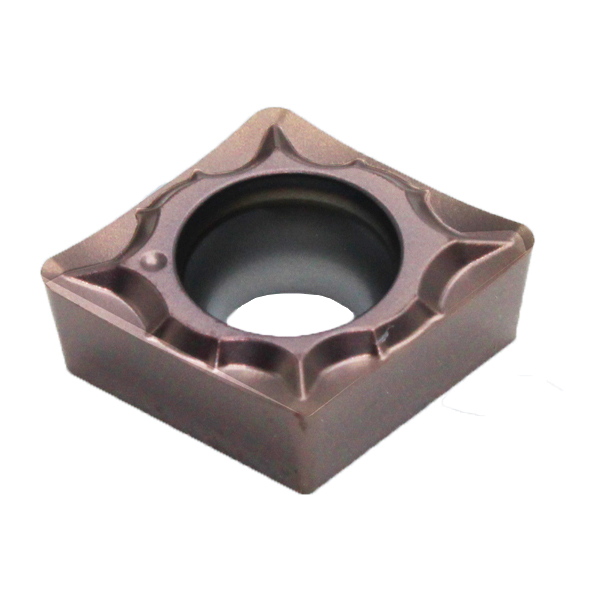

In PVD coating process, a thinner layer of coating is applied on the Insert which makes the edges of the insert sharper. PVD coated Inserts are ideal for difficult-to cut metals such as Stainless Steel and super alloys such as Titanium and Inconel.Titanium Carbon Nitride (TiCN) and Aluminum Oxide (Al2O3) are the most commonly coatings used for Coating Inserts. TiCN has excellent wear resistance while Al2O3 is thermally and chemically stable which protect the insert from high temperature and exposure to chemicals of the coolant.